Get an Estimate Today

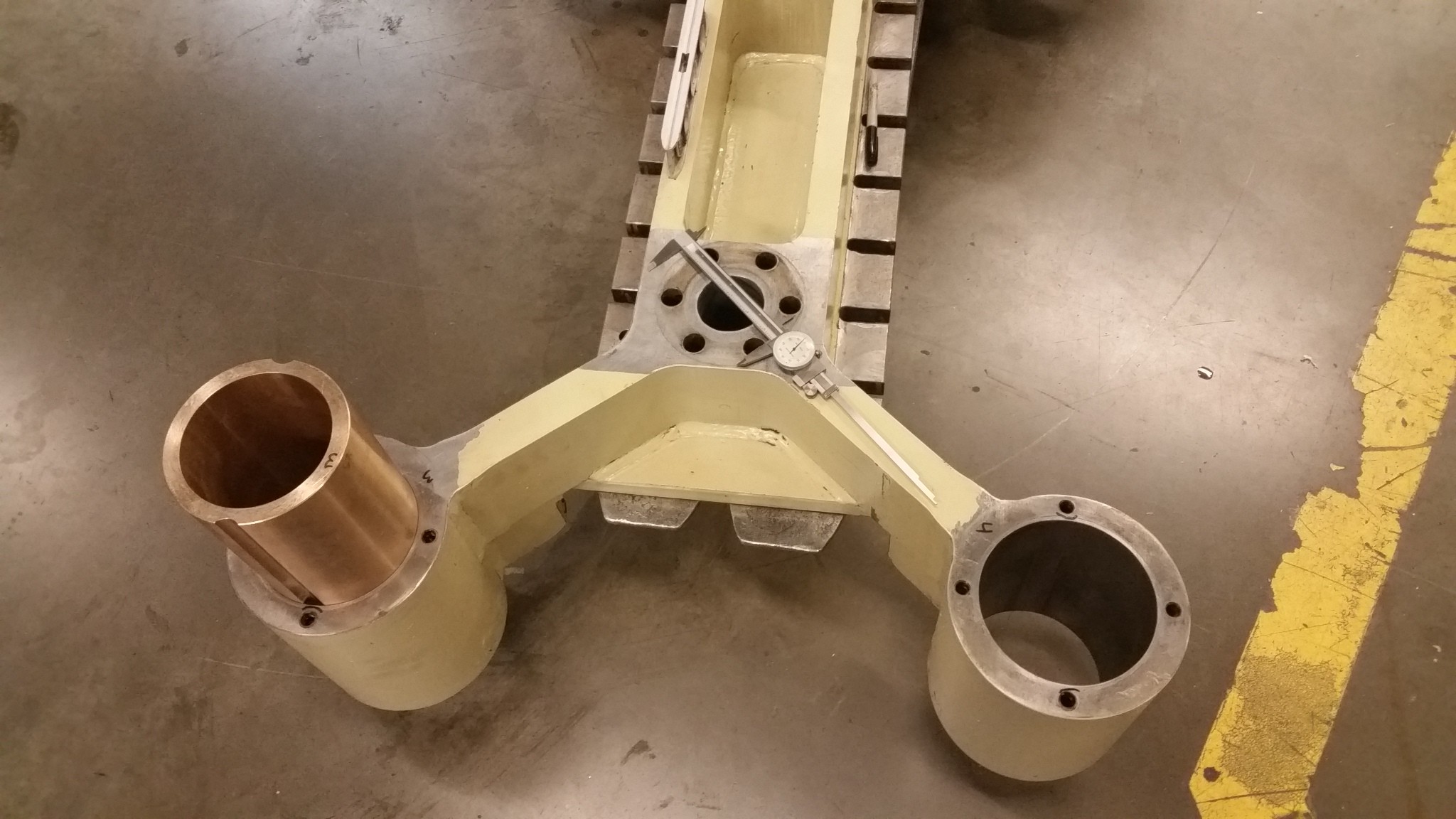

Our skilled technicians provide both in-house and on-site support, from troubleshooting stamping presses, winders, and unloaders to performing extensive repairs on major shop equipment. Whether your equipment requires a minor repair or a complete overhaul, we have the expertise to handle all aspects of maintenance, including electrical and mechanical components, to keep your production processes on track.

Our team of experienced technicians is highly trained in electrical, mechanical, and PLC (Programmable Logic Controller) systems, giving us the capability to address a wide range of equipment needs.

With expertise in the maintenance and repair of stamping presses, mills, lathes, surface grinders, and other essential machinery, we can conduct repairs either at your facility or in our shop. This flexibility allows us to provide efficient, effective solutions tailored to your specific requirements, ensuring your equipment operates at peak performance.

Get a QuoteOur technicians specialize in diagnosing issues across various types of machinery, including stamping presses and winders, to quickly identify and resolve operational problems, reducing downtime.

We offer targeted repair services for essential shop equipment such as stamping presses, unloaders, mills, and lathes, addressing mechanical and electrical issues to maintain smooth operation.

To meet diverse client needs, we provide both in-house and on-site repair options, allowing for maximum convenience and minimal disruption to your workflow.

Advanced Tooling Solutions delivers full machine maintenance services for major equipment, including stamping presses, surface grinders, and other core machinery, restoring them to peak operational condition.

Advanced Tooling Solutions is committed to providing error free product and services on-time, every time while meeting applicable requirements. The core values of our company are based on customer satisfaction.

We specialize in precision stamping services with 4-30 ton Bruderer presses, offering both new tool development and optimization of existing processes. We work closely with clients to customize stamping solutions tailored to their unique requirements, delivering the expertise our clients rely on.

Learn MoreAdvanced Tooling Solutions provides design services with SolidWorks 3D and AutoCAD 2D software, delivering precise tooling and process designs for both prototype and production-grade parts. We create custom solutions to meet each client’s unique needs.

Learn MoreAdvanced Tooling Solutions offers comprehensive machining services, including mill and lathe work, precision cylindrical and surface grinding, and die building and assembly. Our expertise ensures we meet all your tooling needs with precision and reliability.

Learn MoreWe offer expert consulting services to optimize your manufacturing processes. From tooling recommendations to strategies for efficient production and customized problem-solving solutions, we’re here to ensure your operations run smoothly and effectively.

Learn MoreAdvanced Tooling Solutions offers precise inspection services to ensure top quality, utilizing ISO 9001:2015-compliant practices. Our advanced equipment, including an OGP 250 Zip SmartScope and two optical comparators, guarantees accuracy and reliability for every project.

Learn MoreWith the right tools and problem-solving expertise, we take on complex, hard-to-make components, providing solutions tailored to your toughest manufacturing needs.

Learn More